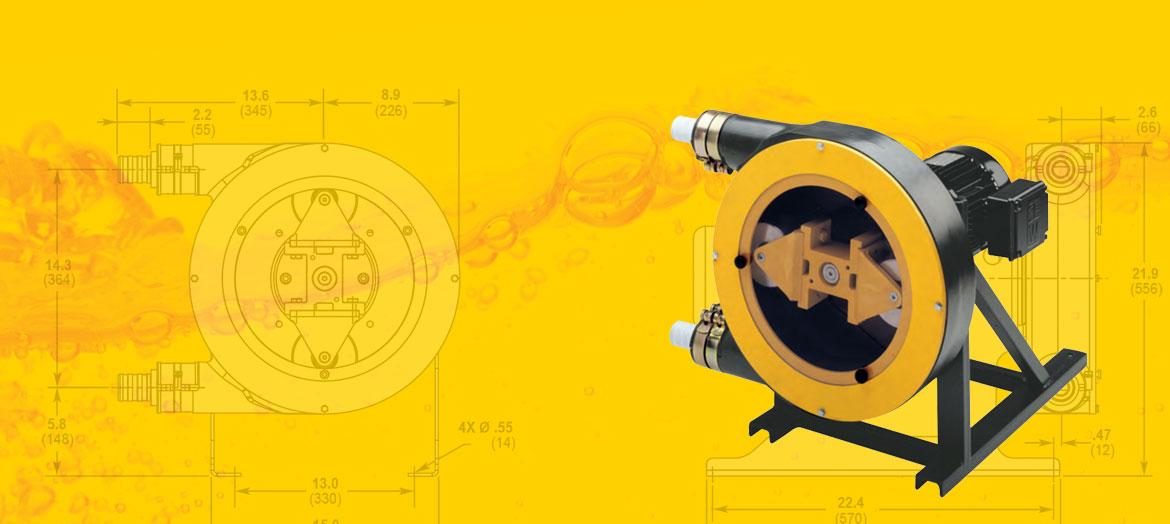

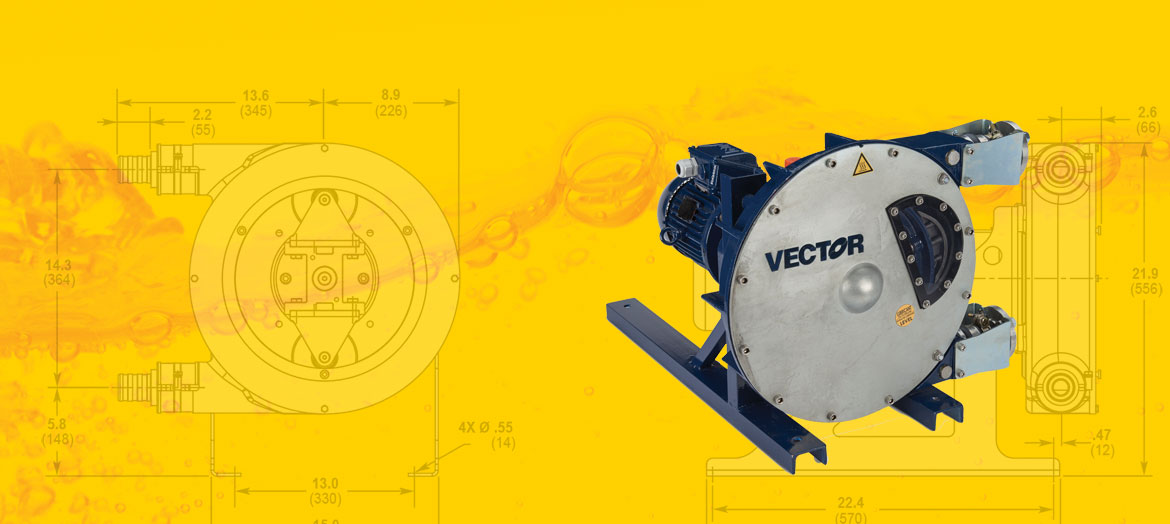

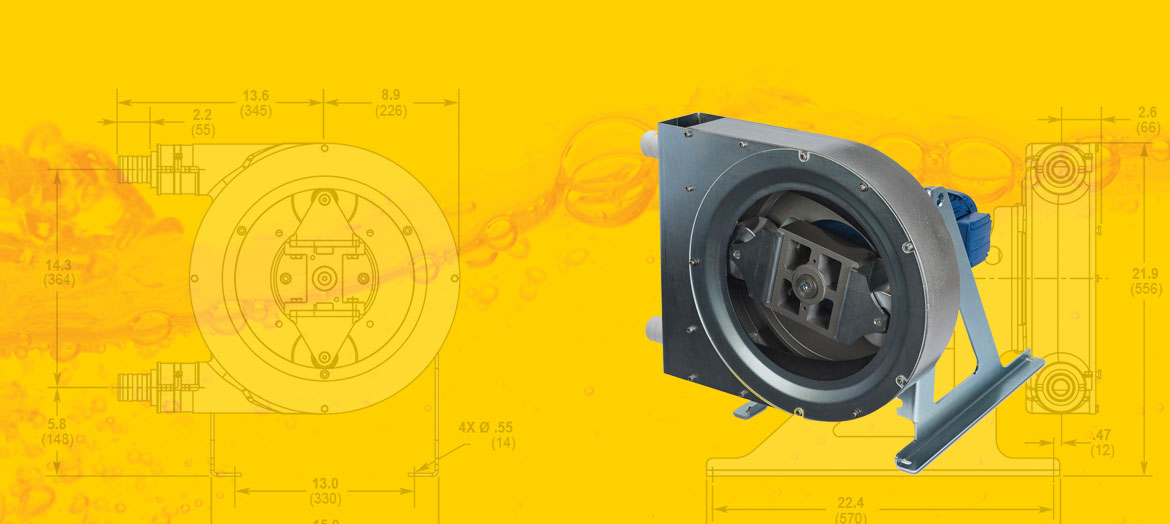

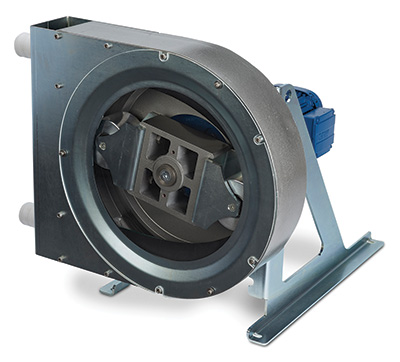

Available in 17 models to handle a wide range of processing requirements, Vector peristaltic pumps are ideal for pumping challenging fluids without altering their composition.

They move high-viscosity (up to 100,000 cps) pasty, pulpy, thick, abrasive, and corrosive solutions as well as fluids containing solids up to 3-1/2 inches (90 mm) in size.